All about Hot Sprue Bushings

This has the benefit that no modifications need to be made at the mold and mildew. hot sprue bushings. The resulting opening at the injected part from the gas intro, can be closed by postinjection.

Our team of Engineers as well as Physicists will certainly guarantee that your intellectual residential property is recognized via the crucial cartridge heating unit. We pay attention, after that act.

Tire mold layout originally starts with decision of the filled with air dimensions of the needed tire size. By utilize of inflated tire as well as development attributes of the tire, initial plyline and also mold dimensions are calculated (Number 14.6). As soon as the mold border measurements, place of the plyline, as well as walk width and depth are understood, the contours of the tread, shoulder, sidewall, and grain components can be developed.

Plyline borders. Figure 14.7. CADAM-developed mold tooth cavity. The primary rate of interest in designing a tire lies in the belt area, bead area, and belt as well as ply cord stress. As radial tires include multiple belts, these layups must be deemed a plan. The rigidity of the radial tire belt package is a feature of belt cord angles, wire gauge, belt scale, and substance stiffness.

Hot Sprue Bushings for Beginners

As an empirical guide, a boost in the stiffness of the belt plan, while maintaining belt width, will certainly boost step wear performance. Number 14.8. (a) Normal four-belt layup for a truck tire. (b) Effect of Gough tightness. The rigidity of a tire belt bundle can be measured by resolution of the "Gough stiffness" (S), which is a procedure of the in-plane flexing rigidity of the stiff belt cable, cable, as well as rubber compound laminate.

Clarifying, Gough identified that a simple beam model of tire building attributes could be made use of to predict loved one walk wear performance - hot sprue bushings. Using both shearing and also flexing minutes in the computation, an empirical formula was acquired defining the rigidity criterion S for a basic laminate( 14.2 )S =P/ d, where lots, P, is the force put on the crown location layup or laminate to offer a deflection d.

Fundamentally, Eq. (14.3) can be streamlined to a design including a basic supported light beam of length L with flexible constants E and also G deflected range d forcibly P as( 14.4 )S= PL 3/48EI +2 PL/8AG, where A is the in-plane cross-sectional area to which the force P is used, as well as I is the minute of inertia of the beam.

For a right/right/left/ appropriate belt arrangement, the belt angle (θ) of the 2nd and also 3rd belts was varied from 10 ° to 26 °. Computation of an optimum belt layup will certainly allow success of the called for Gough stiffness. Structural mechanical computations such as finite-element analysis (FEA) are made use of to analyze both the inflated and loaded deflected shapes of a tire cross-section as well as the resulting stress-strain partnerships in the belt location.

The Ultimate Guide To Hot Sprue Bushings

Figure 14.9 reveals a durable vehicle tire in the crammed as well as unloaded states. The thickness of grids is created so as to protect the crucial functions of the tire cross-section geometry while keeping the complete variety of grid points. Figure 14.9. Finite-element structure of a heavy-duty truck tire. In an evaluation of the belt package, 3 conditions can be assessed that allow calculation of the variety of stress energy thickness: inflated tire condition, filled tire problem 180 ° away from the footprint, and also packed tire problem at the facility of the footprint.

It reveals that the pressure power density in megapascals in a filled with air tire is comparable to that in a tons tire 180 ° away from the impact. At the center of the footprint in a loaded problem, however, the pressure energy density at the belt side has actually enhanced from the array 0.01-- 0.27 to 0.05-- 0.51 MPa.

Figure 14.10. Finite-element evaluation of belt location showing pressure energy thickness (in MPa). (a) Rising Cost Of Living. (b) Loaded 180 ° away from footprint. (c) Packed at facility of footprint. Comparable to the belt area of the tire, the bead area also lends itself to finite-element evaluation. Changing grid details to the bead enables analysis of the ply end strains on inflation as well as in a loaded state as the tire makes a complete transformation.

In today's globe of injection molded products, choices on mold and mildew design and also building and construction are commonly driven by first rate and also shipment. This manner of mold and mildew purchase can place the shaped part in a position of not being at its lasting financial benefit for the business generating the initial generation of components, and also not adding a reasonable share to the lower line profits for also short-run mold and mildews.

Hot Sprue Bushings for Dummies

As a matter of fact, a competitor with mold and mildews made for lasting parts manufacturing, at the most effective ROI versus the production run, will have an economic edge in rebidding, specifically if the same procedures are reflective of the overall corporate expectation. Complying with are points to consider for both short-run and also long-run shot molded plastic parts. hot sprue bushings.

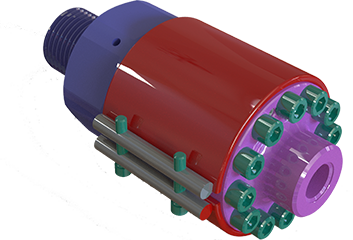

In the building of a cold bushing, single-cavity mold with edge-gating of the part, added mold size is needed to suit the runner and countered of the dental caries from the sprue bushing. Well-designed systems will provide a reduced profile warm runner to relocate the material to the balanced out for edge-gating with the least increase in mold dimension.

By utilizing a valve gateway to the parting line, less material is required per shot, which conserves power as well as decreases scrap (sprues) or the portion of regrind made use of. The economic situations of using a warm jogger to change mold balanced out are such that they ought to be taken into consideration for all parts above 50g with a predicted manufacturing life above 150,000 components.

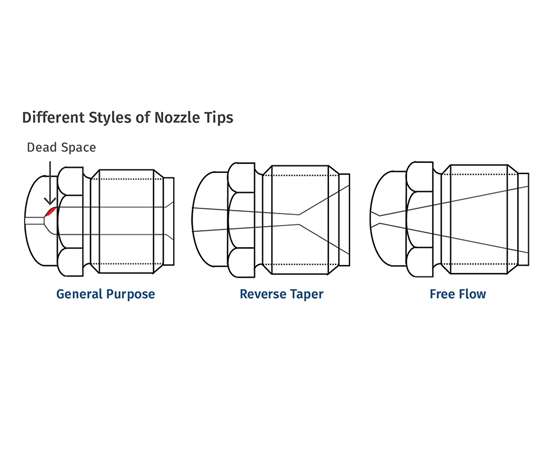

The use of a sprue bushing to straight entrance right into a single-cavity mold and mildew provides numerous benefits in the building and construction and also operation of the mold and mildew over the chilly jogger type. The mold and mildew base dimension is just depending on the part requirements and also will certainly make use of the tiniest press required. When utilizing a cool sprue bushing, a sprue is created that need to be eliminated, leaving a mark, which usually must be removed by secondary operations if appearance or maximum elevation of the sprue rest are part factors to consider.

you can try these out informative post Visit This Link