Discover the Advantages of Using Industrial Scales in Your Business Operations

Integrating industrial scales into your company procedures provides a plethora of benefits that can change your operational structure. From enhancing precision in dimensions to improving total performance, these devices play a crucial function in reducing waste and making certain conformity with industry criteria. As companies significantly look for to enhance their procedures, comprehending the complex advantages of industrial ranges becomes crucial. What ramifications could these enhancements carry your operational technique and profits?

Improved Precision and Accuracy

Accomplishing boosted accuracy and accuracy in dimensions is vital for businesses that count on commercial ranges. These ranges play an essential role in different industries, consisting of production, logistics, and food handling, where precise weight measurements straight influence operational effectiveness and product top quality. Accurate measurements avoid expensive errors, guarantee conformity with regulations, and enhance client contentment by providing products that meet defined weight requirements.

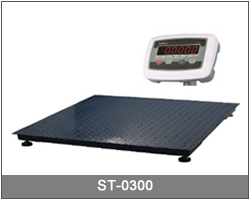

Industrial scales are developed to offer high levels of accuracy through advanced technology, such as lots cells and electronic displays, which reduce human error and environmental elements that can impact readings. Regular calibration and maintenance of these ranges are necessary to maintaining their performance, making sure that they produce reliable information in time.

Furthermore, accurate dimensions promote far better stock monitoring, permitting organizations to track supply degrees extra successfully and minimize waste. By making use of commercial scales with enhanced precision and precision, business can optimize their manufacturing processes, eventually bring about enhanced success. In summary, the assimilation of high-precision commercial scales right into service operations is not simply a financial investment in tools yet a calculated action towards operational quality and sustainability.

Enhanced Operational Performance

Industrial scales considerably boost a service's operational effectiveness by streamlining procedures and minimizing time spent on measurement-related jobs. By automating weight dimension, these scales decrease hands-on handling and the possibility for human error, resulting in even more reputable and consistent results. This automation allows personnel to concentrate on higher-value activities, ultimately boosting efficiency and resource appropriation.

In addition, the combination of commercial scales with supply management systems allows real-time tracking of products and products. This ability reduces delays in processing and makes certain prompt restocking, avoiding expensive downtimes. Organizations can also better handle supply chain logistics, as accurate weight measurements help with ideal shipping and handling practices.

In markets such as manufacturing, food processing, and logistics, the capability to swiftly and properly gauge weights can significantly impact throughput times. The efficiency got from making use of commercial scales equates into quicker turnaround times, enabling firms to meet customer demands quickly and efficiently.

Conformity With Market Specifications

Exactly how can companies guarantee they fulfill the stringent needs established forth by market guidelines? One reliable method is the combination of commercial ranges right into their procedures. These scales are created to give exact dimensions, which are essential for compliance with different governing requirements, including those related to security, high quality, and weight control.

Accurate considering plays an essential function in industries such as food production, drugs, and manufacturing, where non-compliance can cause significant financial losses and lawful consequences. By utilizing adjusted industrial ranges, organizations can make sure that their items satisfy specified weight needs, consequently reducing the danger of charges or remembers.

Furthermore, several industrial ranges are geared up with innovative features such as information logging and automated coverage, which help with conformity audits and regulative evaluations. This not just simplifies the documentation procedure yet likewise enhances transparency in procedures.

Moreover, regular maintenance and calibration of ranges are vital to promote accuracy and reliability. By prioritizing these techniques, organizations can cultivate a culture of conformity, guaranteeing that they not just meet market requirements yet also improve their reputation as credible entities within their particular markets.

Price Decrease and Waste Minimization

Acknowledging the effect of precise evaluating on functional performance, businesses can leverage industrial ranges to dramatically reduce costs and minimize waste. By guaranteeing accurate measurements, business can enhance their material usage, avoiding over-ordering and too much inventory, which directly adds to set you back savings.

Additionally, exact evaluating assists identify inconsistencies in material delivery, allowing for prompt improvements and minimizing losses associated with perishing or misallocation. In sectors where raw materials are expensive, such as manufacturing and food production, also mild inaccuracies can result in substantial financial losses.

Executing industrial ranges also boosts advice production procedures by enhancing process. When materials are considered properly before handling, it minimizes the likelihood of rework or item recalls, which are costly and destructive to a business's track record.

Furthermore, by enabling better monitoring and analysis of product consumption, companies can recognize ineffectiveness and implement targeted improvements. This data-driven strategy not only promotes a culture of continual improvement yet also sustains sustainability campaigns by decreasing waste - Industrial Scales. Inevitably, the tactical usage of industrial ranges not only safeguards earnings yet likewise promotes accountable source monitoring

Adaptability Across Industries

The adaptability of industrial scales is noticeable in their application throughout a multitude of sectors, consisting of production, food handling, logistics, and pharmaceuticals. In manufacturing, these ranges guarantee accuracy in material measurement, which is vital for keeping product official site top quality and minimizing mistakes. Their durable design accommodates hefty loads, making them excellent for manufacturing facilities where big amounts of products are refined.

In the food handling sector, compliance with security and quality regulations is vital. Industrial scales facilitate precise ingredient measurement, assisting in uniformity and adherence to health criteria. In logistics, weight verification is necessary for shipping and transport, optimizing lots distribution and guaranteeing compliance with policies concerning weight limitations.

The pharmaceutical market likewise benefits considerably from industrial scales, as they are important for accurate formulation and dose measurement. Precision in this field can straight impact individual safety and treatment efficiency.

Conclusion

Incorporating commercial ranges into organization operations returns substantial benefits, including boosted accuracy and precision, boosted operational performance, and compliance with market criteria. The implementation of these scales contributes to cost decrease and waste reduction, while their versatility permits for application across different sectors. Eventually, the application of commercial scales not only enhances supply monitoring however additionally fosters a culture of compliance, thus reinforcing market credibility and client complete satisfaction.

Industrial scales significantly boost a service's operational efficiency by streamlining procedures and decreasing time spent on measurement-related jobs.Incorporating commercial scales right into service operations returns significant benefits, including boosted accuracy and accuracy, enhanced functional performance, and compliance with sector requirements.